OTR Waste Tire Recycling Line

The OTR Waste Tire Recycling Line is specially designed to process oversized industrial and mining tires, which are typically difficult to handle due to their large size and high steel content. This recycling system offers two tailored solutions based on the tire diameter, ensuring efficient size reduction and high-purity rubber powder output.

Raw Materials and Finished Products

Applicable Raw Materials: Designed for large engineering, mining, and heavy-duty truck tires with diameters ranging from 1800mm to 4000mm.

Final Products: Rubber powder or rubber granules with adjustable particle sizes and purity levels reaching up to 99%. Suitable for use in sports surfaces, rubber mats, reclaimed rubber production, and more.

Features of The OTR Waste Tire Recycling Line

- Designed for Extra-Large Tires: Specially built to process oversized OTR tires with diameters ranging from 1800mm to 4000mm, such as mining and construction tires.

- Heavy-Duty Equipment Configuration: Large-scale drawing machines, disintegrators, shredders, etc., specially designed for the treatment of OTR tyres.

- Customized Processing Options: Two processing schemes are available to suit various tire sizes, structures, and materials, offering flexible solutions tailored to customer requirements.

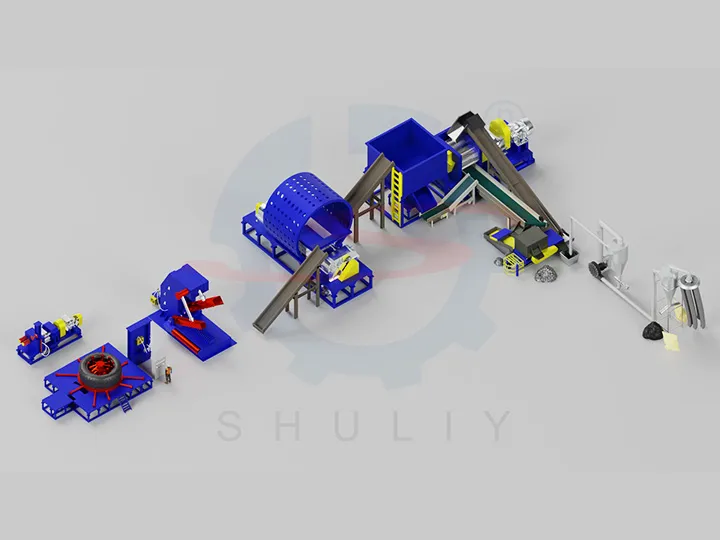

Two Solutions of OTR Tire Recycling Line

For the OTR waste tire recycling line, we offer two solutions that you can refer to. Of course, we can also provide customised solutions according to the specific needs of our customers.

For OTR Tires with Diameter 1800–4000mm

This solution is ideal for large OTR tires used in heavy-duty machinery. It includes the following equipment:

- OTR Tire Debeader Machine – Extracts the thick steel wire from tire beads.

- OTR Cutter – Cuts large tires into manageable sections.

- Tire Shredder (Model 1200 or above) – Shreds tire blocks into smaller rubber chips.

- Rubber Crusher (Model 450 or above) – Grinds chips into fine rubber powder.

- Nylon Fiber Separator – Removes nylon fibers from rubber.

- Rubber Powder Collection & Conveyor System – Collects and transfers finished rubber powder.

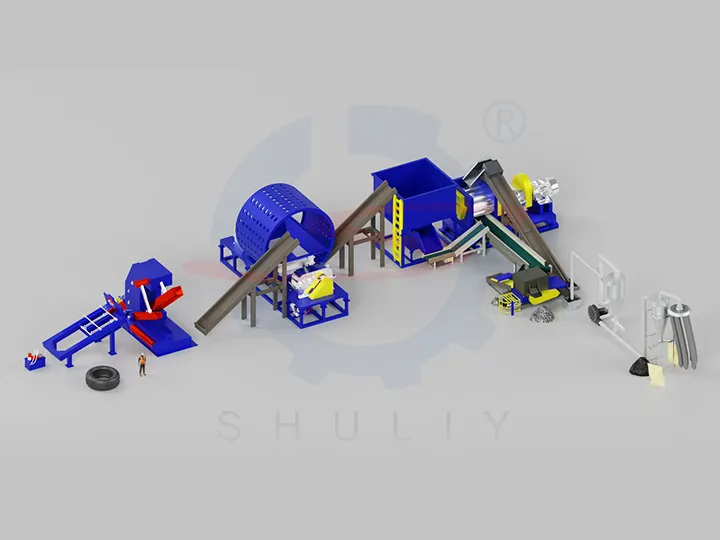

For OTR Tires with Diameter Above 2100mm

The pre-treatment stages are different and can be selected by the customer according to specific needs.

- OTR Dismantling Machine – Cuts the tire ring and separates the sidewall from the tread.

- OTR Cutter – Further reduces tire size.

- OTR Steel Wire Separator – Effectively removes embedded steel components.

- Tire Shredder Machine(Model 1200 or above)

- Rubber Grinder (Model 450 or above)

- Nylon Fiber Separator

- Rubber Powder Collection & Conveyor System