Tire Strip Cutter

In the waste tire recycling process, the tire strip cutter plays a vital role after the sidewall cutter. It is specially designed to cut de-beaded tires into rubber strips, making it easier for the next step—block cutting or shredding.

Usage of Tyre Strip Cutting Machine

The primary function of the tire strip cutter is to slice whole tires into uniform strips, simplifying the feeding process for the tire block cutter. Compared to processing whole tires directly, pre-cut strips improve efficiency, reduce energy consumption, and lessen wear on downstream equipment.

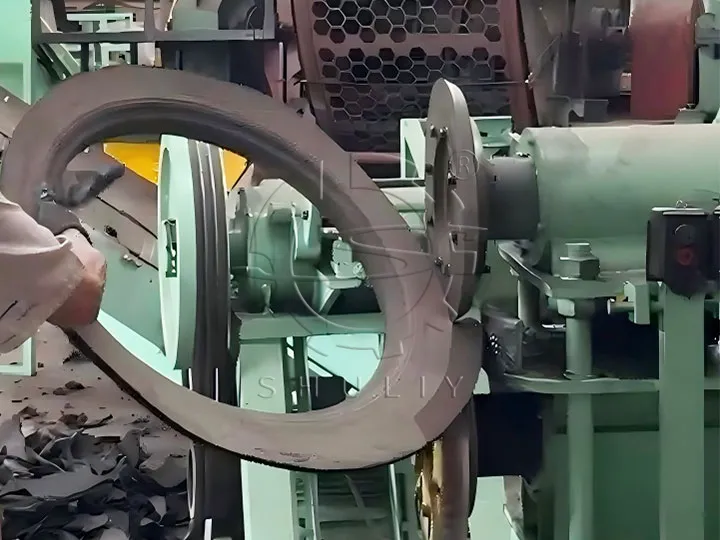

This video shows the entire process of the tire strip cutting machine efficiently cutting de-beaded tires into uniform rubber strips, preparing them for the next step of block cutting.

Key Features of The Tire Strip Cutter

- Adjustable Strip Width: The width of the rubber strips can be adjusted to meet different processing requirements.

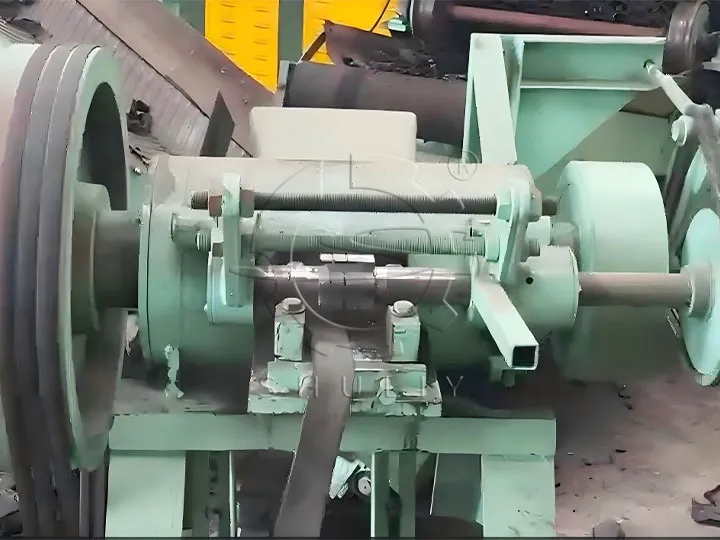

- High-Efficiency Cutting: Equipped with two specially designed high-strength circular blades for continuous, clean cutting.

- Wide Application: The standard model is suitable for tires with a diameter of less than 1200mm, including car and truck tires.

- Customizable Options: For larger tires (diameter over 1200mm), customized models are available to meet various recycling needs.

- Stable Structure: Robust frame, smooth operation, easy to operate and maintain.

Waste Tire Strip Cutter Specifications

The technical parameters below are for reference only. For more detailed and professional information, feel free to leave us a message on our website — we’ll get back to you promptly.

| Motor power | 5.5KW |

| Capacity | 1000kg/h |

| Motor speed | 45r/min |

| L*W*H | 1.3m*0.8m*1.65m |

| Weight | 850kg |

| Size of cutting strip | 3-5cm wide strip |