Fully Automatic Rubber Powder Production Line

The fully automatic rubber powder production line efficiently processes waste tires (≤1200mm) into rubber powder or granules through a fully automated system, from shredding to final collection, minimizing labor and ensuring consistent output.

Application & Function

This production line is ideal for tire recycling plants aiming to produce high-purity rubber powder or granules for various end uses, such as rubber mats, playgrounds, road surfaces, or regenerated rubber products.

The output particle size can be adjusted according to customer requirements, and with the integrated magnetic separation and nylon fiber removal systems, the final rubber powder purity can exceed 99%.

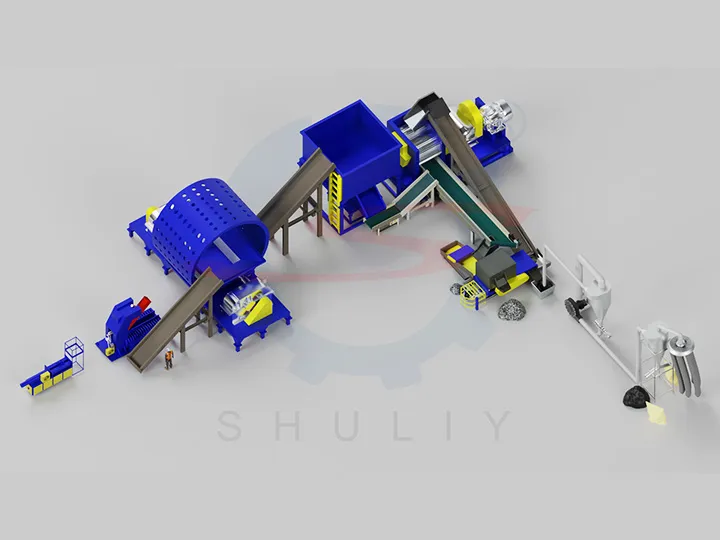

Available Configurations of Rubber Powder Production Line

To meet different production needs and factory layouts, the line is available in three configurations:

Standard Full Line with Separate Wire Drawing and Cutting

- Tire Bead Wire Drawing Machine: Pulling the rim out of the tyre.

- Tire Cutting Machine: Cut the tyre into three small sections.

- Tire Shredder: Shred the tyres into 3-5cm pieces.

- Rubber Crusher: Grinding of rubber blocks into powder or granules, a step that includes crushing, sieving, and magnetic separation.

- Nylon Fiber Separation System: Removes nylon fibers.

- Collection & Conveyor System: Rubber powder collection.

This configuration provides complete front-end separation and is ideal for users requiring maximum control over input material size and wire removal.

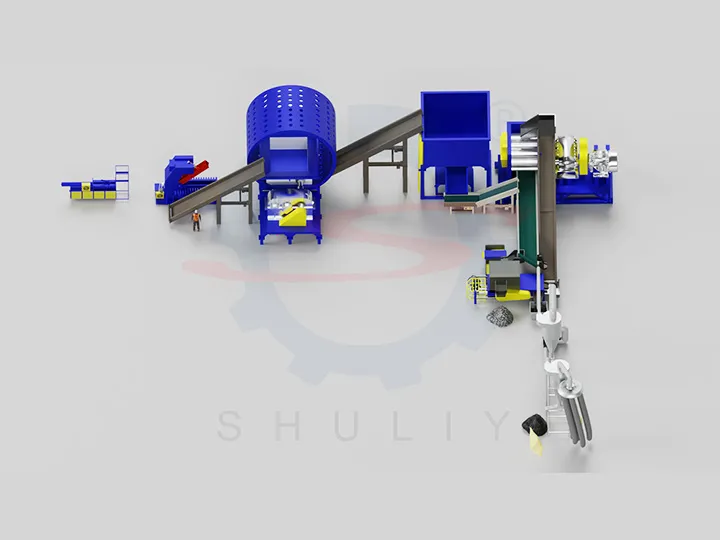

Diverse Pretreatment Configurations

- Tire Steel Wire Separator and Cutting Machine: Remove the part of the tire containing the rim on both sides while cutting off the other part of the tire.

- Tire Bead Wire Remover Machine: Separates steel wire from rubber.

- Industrial Tire Shredder: Breaks tires into smaller blocks.

- Rubber Crusher Machine: Final grinding and powdering.

- Nylon Separator: Nylon fiber removal.

- Collection Conveyor: Rubber powder collection.

Simplified Configuration for Pre-treated Tires

- Tire Recycling Shredder: Shred the tyres into small pieces.

- Rubber Crusher Machine: Produces rubber powder.

- Fiber Separator: Removes non-metal fiber.

- Collection Conveyor: Transports and collects the end product.

This simplified setup is suitable for operations that already receive pre-cut or bead-removed tires, focusing more on shredding and powder processing.

Features of the Rubber Powder Production Line

- Fully Automated Workflow: From shredding to powder collection, reducing manual handling and improving safety.

- Flexible Output Size: Adjustable rubber granule or powder size to meet various downstream applications.

- High-Purity Output: Dual magnetic separation and fiber removal systems ensure over 99% purity.

- Customizable Design: Each layout can be tailored to your plant size and production goals.

Whether you’re upgrading an existing line or setting up a new tire recycling facility, the fully automatic rubber powder production line offers a scalable and efficient solution for high-value rubber powder production.

This video showcases the working process of our fully automatic rubber powder production line. From waste tire shredding to fine rubber powder collection, the entire process is fully automated, minimizing manual labor and ensuring high efficiency.