How to Choose the Right Configuration of Tire Recycling Line?

In a waste tyre recycling project, a reasonable configuration of a tire recycling line that suits one’s needs is the key to achieving stable operation and return on investment. The configuration of the recycling line should be flexibly adjusted due to the different conditions of the customer’s raw material type, capacity demand, product usage, site…

In a waste tyre recycling project, a reasonable configuration of a tire recycling line that suits one’s needs is the key to achieving stable operation and return on investment.

The configuration of the recycling line should be flexibly adjusted due to the different conditions of the customer’s raw material type, capacity demand, product usage, site budget and so on. This article will start from several important aspects to help you understand how to choose a suitable waste tyre recycling line solution.

Define the Tyre Type

In the tire recycling process, there may be differences in the equipment configuration corresponding to different types and sizes of tyres. Common waste tyres include:

- Car tires: relatively small size, simpler structure, light wear and tear on equipment;

- Truck tires: thicker carcasses, higher steel content, higher strength equipment required;

- Construction vehicle tyres (OTR tyres): diameters of up to 3 metres or more, needing to be pre-cut and handled in conjunction with specialist separation equipment.

Therefore, it is recommended that the customer count the type of raw material and the size range before selecting a tyre. We will recommend the appropriate tire recycling line according to the size of the tire.

Clarifying Capacity Needs

Different customers have varying requirements for production capacity. Small recycling plants may aim to process only a few tons of waste tires per day, while medium to large enterprises often seek higher processing capabilities. It’s important to note that output capacity is closely related to the size of the rubber powder.

- The coarser the rubber powder particles, the faster the processing speed and the higher the overall output.

- If finer rubber powder is required, additional grinding steps are necessary, which will reduce the output per unit of time accordingly.

Therefore, customers should determine a reasonable target for particle size and production capacity based on market demand or their own sales channels.

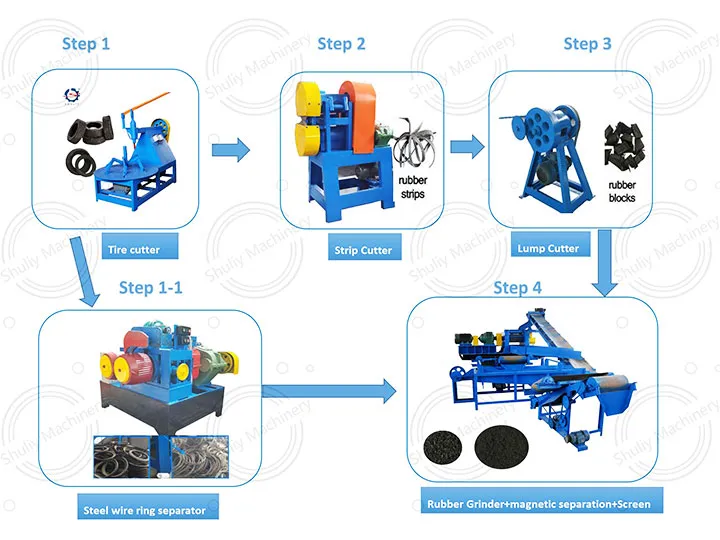

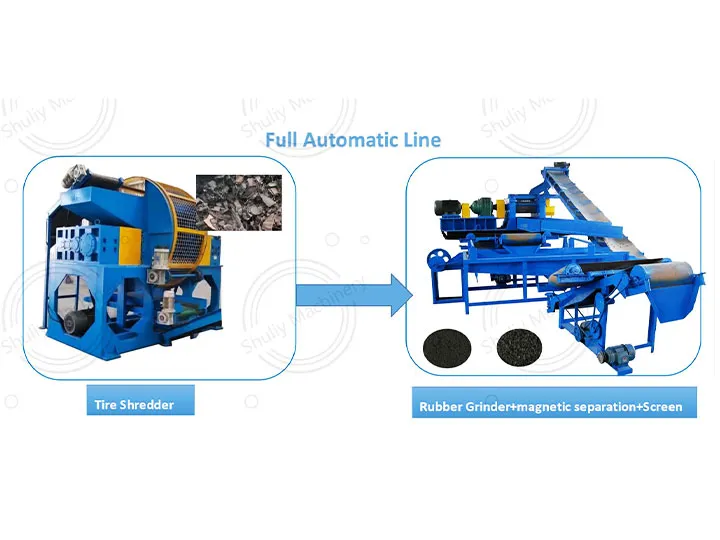

Determine the Use of Finished Products

After tire recycling, the output can be either rubber granules or rubber powder, each serving different downstream customers:

- Rubber Granules: Commonly used for running tracks, artificial turf infill, rubber mats, etc.

- Rubber Powder: Used in reclaimed rubber production, rubber product manufacturing, and asphalt modification for road construction.

Our rubber crusher is equipped with screening and magnetic separation system, the purity of rubber powder can reach 99% and above.

Consideration of Automation Level Requirements

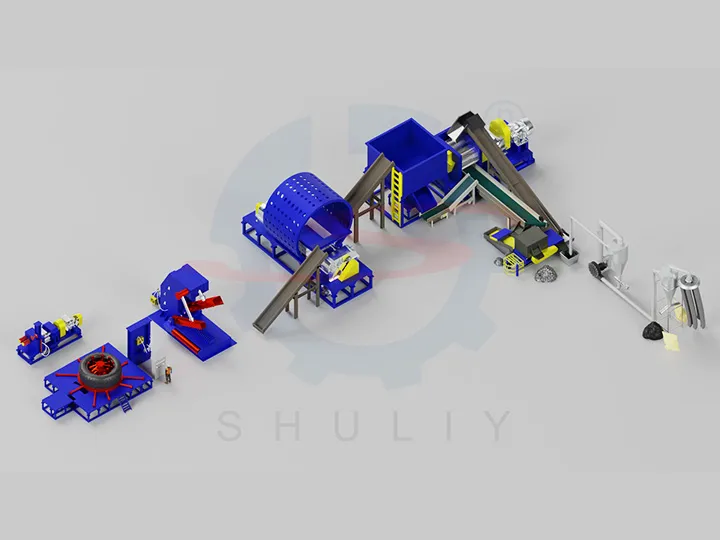

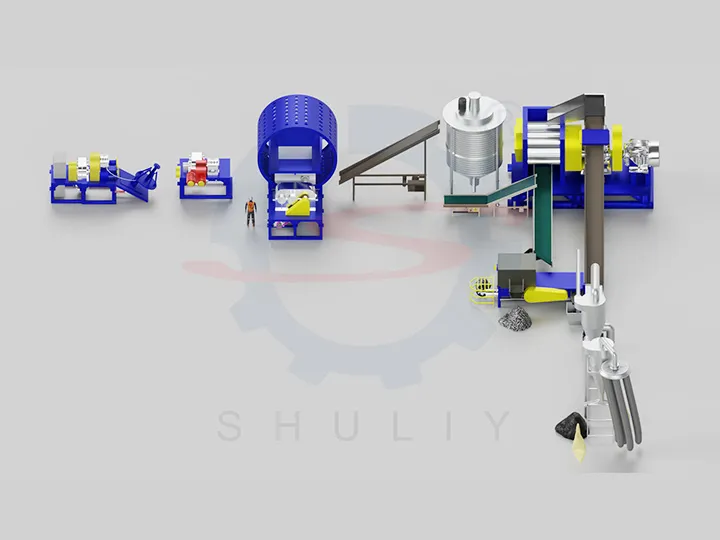

The automation level of a tire recycling line affects operator requirements, operational efficiency, and long-term operating costs. We can provide different levels of automation solutions based on the customer’s needs:

- Semi-automatic recycling line: from pre-processing to grinding, the whole tire recycling line requires 2-3 labourers.

- Fully automatic tyre recycling line: from shredding, grinding, sieving, magnetic separation to finished product collection, the whole process is automated.

Customers can choose the appropriate level of automation according to their needs.

Assess Site and Budget Conditions

A waste tire recycling line typically consists of multiple equipment units, and the required floor space varies depending on the configuration. Before starting the project, it is recommended that customers evaluate the following factors:

- Available site area and layout;

- Whether the power supply capacity is sufficient;

- Environmental conditions for handling dust, noise, etc.;

- Overall investment budget.

Once these conditions are clarified, we can better design a layout plan and recommend a more cost-effective configuration.

Choosing the right waste tire recycling line is not just about purchasing equipment — it’s a comprehensive evaluation of project feasibility and potential returns. By assessing tire types, capacity goals, product applications, automation requirements, and site and budget conditions, businesses can lay a solid foundation for their project from the start.

With years of industry experience, we welcome you to contact us for a customized equipment solution and professional technical support.