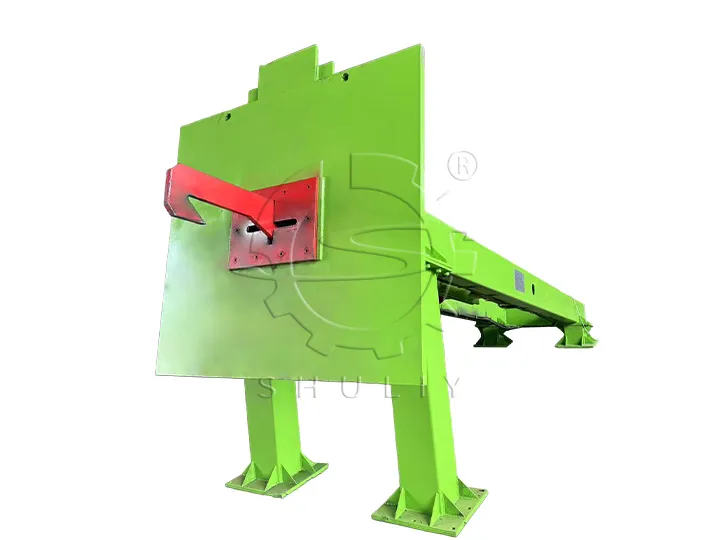

OTR Debeader

The OTR debeader is a wire pre-processing machine designed for the treatment of OTR tires, mainly for the direct extraction of steel wires from the bead of tires with diameters between 1800mm and 4000mm.

Main Functions and Applications

The OTR debeader is primarily used to pull out the thick, hard steel wire from the bead of an OTR tire in one piece. The steel wire in the bead of an engineering tire is so strong and deeply embedded that if it is not pre-treated and goes directly into the tire recycling shredder, it will cause rapid wear and tear or even damage to the knives.

By separating the steel wire first, it not only improves the service life of the equipment, but also lays the foundation for subsequent cutting, shredding and sorting.

How Does The OTR Debeader Work?

The operator will place the large tire at the pulling hook of the equipment, and the hydraulic system will control the grappling hook to fix the tire, and then start the pulling device to strongly pull the steel wire in the bead directly out of the tire. The whole set of operations is safe and efficient, and can be adjusted according to different sizes of tyres.

Parameters of OTR Tire Debeader Machine

Below are the technical specifications of our OTR tire debeader machine, designed for efficient bead wire removal from large OTR tires.

| Power | 22+3kw |

| Length of machine | 4 metres |

| Weight | 9500kg |

| Handling of tire size | 1800-4000mm |

| Production capacity | 2 minutes/pc |