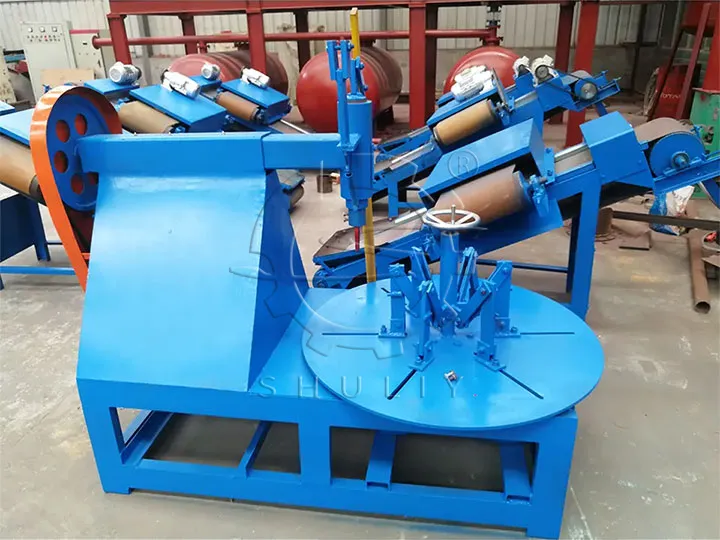

Tire Sidewall Cutter

In the process of recycling used tires, the tire sidewall cutter plays a vital role as a pre-treatment machine. It is specifically designed to cut off the sidewalls of scrap tires with precision. This step greatly improves the efficiency of subsequent processing, reduces wear on other equipment, and is an indispensable part of a complete tire recycling line.

The Role of The Sidewall Tire Cutter

The tire ring cutter is designed to cut the wire sidewalls of tyres, especially for common small car and truck tyres. The machine uses high-strength alloy knives to quickly cut the sidewall portion of the tyre, helping to break down the whole tyre into smaller, more regular parts, thus facilitating the subsequent processing.

Cutting the sidewall containing steel wire also facilitates the separation and recovery of steel wire. Due to the hardness of the steel wires, they could easily damage the equipment if they were to enter the tire shredder directly. Pre-cutting with the Tire Sidewall Cutter not only protects the subsequent equipment but also improves the purity and recycling quality of the rubber granules.

This video shows the whole process of a tyre bead cutting machine efficiently cutting the outer bead of a tyre in preparation for the subsequent disassembly process.

Features of The Tire Ring Cutter

- High Efficiency: Fast cutting speed supports continuous operation, improving overall productivity.

- Easy Operation: Equipped with a simple control system that is user-friendly and easy to maintain.

- Wide Application: Suitable for various tire sizes, including car and light truck tires.

Key Parameters of The Tire Sidewall Cutter

The following technical parameters are for reference only. You can leave a message on our website, we will send you more professional and comprehensive information.

| Motor Power | 4KW+0.75KW |

| Capacity | 40pcs/h |

| Handling Tyre Sizes | ∮650-1250 mm |

| L*W*H | 1.8m*1.3m*1.6m |

| Weight | 650kg |

Working Principle

The working principle of the tire sidewall cutter is mainly to drive the cutter to cut the steel wire bead part (i.e, the outer bead of the tyre) of the waste tyre from the carcass by means of a electric drive unit. The basic process is as follows:

Fixed Tyres

Place the tyre on the platform and rotate the tensioner operating handle to brace the tensioning assembly and hold the tyre in position.

Blade Alignment

The cutting blade is positioned near the edge of the sidewall, where the steel bead is located.

Cutting Begins

Starting the machine, the cutter is rotated or propelled by the motor to make contact with the tyre and cut it.

Bead Removal

The blade cuts along the tire’s circumference, separating the steel bead completely from the main body of the tire.